Scheme of a beera under water. Production of a bead for drilling wells yourself

Not always on a summer cottage or a country house for water supply is rational to construct expensive. The sites used only for the garden and the venue of picnics in the summer months are usually equipped with or well-type wells, because there is no need to obtain special permits, technical conditions and the development of a technical passport. In addition, the bur for such purposes can be made and assemble yourself.

Features of manual drilling

Favorable conditions for drilling a well manually are:

- groundwater at a depth of 20 m;

- soil without solid rocks that make drilling manually.

Manual well drilling can be carried out in two ways:

- rotational;

- rope-shock.

The meaning of the cable-shock method is to build a well, with a relatively large height in it, a heavy tube with an acute end tied with a rope to the frame is thrown. The soil is separated from the blows of this design, and gets inside it. Then the pipe rises to the surface of the swan and is released from the breed accumulated in it. This is a deepening. The advantage of shock drilling is that one person can be used in it.

Drilling with a rotational method is made by a tool that can crash into the ground with rotation and raise the ground to the surface. For this method of drilling, two people need to use to ensure the rotation of the drilling rod using fittings or pipes. As the structure of the borah in the ground is deepened, it is increasing with additional turbid tubes.

Upon completion of drilling work, the casing of the casing in the well is lowered.

Variety of boots

Spiral bur - This is a drilling tool by cutting into a soil with special cutting plates welded to the tool rod.

In addition to the Bura itself, in order to build a well, you need: holder and additional junction tubes to build up the desired length of the design.

Bur for or boring - This is a massive tool consisting of a pipe with an ulute placed on the bottom. It can only be applied if there is a tripod, providing the height of the boom lift 2-2.5 m.

Bo-spoon - The device by which rotational drilling is made, as in the case of the use of a screw tool, only it is equipped with a large metal cylinder on the end of the rod. Such a design ensures an effective accumulation of strongly loose or wet soils, with which the usual screw boring is well coped. It is equipped with a holder and additional connector tubes to adjust the length of the tool.

How to make a cable-shock

The shock bead mechanism is quite simple in the device. In order to make it and collect the following material resources and equipment: a thick-walled pipe of the required size, corners, sheet steel, roulette, a bulgarian, welding machine and manual or automatic winch. To make and collect shock drip, some actions in such a sequence should be performed:

- A tripod is assembled high no less than a meter.

- The top of the tripod is equipped with a special node that allows you to set a manual or automatic winch.

- Pushes a shock tool.

This requires a pipe with an outer diameter that corresponds to the diameter of the future well. One end is breeding a piece of thick steel. Then the hole is performed in it in order to fix the cable. And at the shock end of the pipe across the circumference, sharpening are made. To ensure the strength of these elements, they must be hardening. And also the tool should be equipped with additional weightlifiers.

The basis for placing the working tool is prepared. A shallow hole is cut in the ground. Then the car for rope drilling is attached to tripods and is placed in such a way that it can fully immerse themselves in the prepared area under its own weight.

How to make a spiral burrow?

To independently make a spiral car at home will need such tools, equipment and materials:

- welder;

- yardstick;

- bulgarian;

- steel rod with a diameter of 25 mm required length as a future rod;

- tube with a diameter of 25-32 mm;

- steel discs (you can apply the dried saw blade from the circular plate of the desired size).

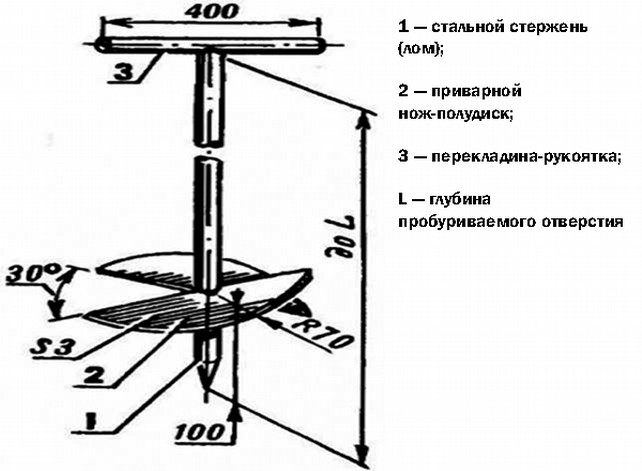

The procedure for which should be followed in the independent manufacture of the screw bora.

- It is necessary to cut the disc from steel into two semicircles.

- Both of the former disk need to sharpen well.

- The steel rod with a diameter of 25 mm also need to be sharpened on the one hand.

- From sharpening, at a distance of 20-25 cm you need to leave a mark in the form of notches.

- To the marked place on the rod should be welded at an angle of 20 degrees, harvested earlier, semicircles from the steel disk.

- The total angle between semicircular blades should be 40 degrees.

The sharpening is better to entrust a professional or a person who can accumulate tools. Because the quality of sharpening depends on how the future tool will crash into the soil, and therefore the speed of drilling well.

Hypothetically, auger boring can be made using a steel spiral for this. To do this, it is necessary to get the strip of instrumental steel, heat it to a temperature at which it can be bent into the helix with the required step and the corresponding diameter. Further, we harden the spiral, and then welcome to the rod. However, at home, to fulfill these actions qualitatively almost unreal.

Materials for the manufacture of a bora

Bur-spoon is made of materials that will always be on the plot. Even an unnecessary automobile gas cylinder with a diameter of 22 cm. To work, you will need tools and materials such as:

- steel pipe of the required diameter;

- gas cylinder with a diameter of 22 cm;

- corner steel;

- angular grinding machine or bulgaria;

- electric welding machine;

- yardstick.

How to make a born spoon

Procedure for the manufacture of a spoonful bora

- From the cylinder, it is necessary to cut off a piece of 25 cm long.

- At the end of the cut plot, you need to make cuts that will be used as cutting edges.

- Cut the pastes from which the soil will be removed, covered inside the cylinder during drilling, the size must be 50 * 200 mm.

- For fastening the future handle, the steel pipe is quite suitable.

- In the opposite side of the cutting end of the cylinder, you must perform a hole for the pipe that should be welcomed.

- You can enhance this design by welding to it jumpers made of the same pipe.

- Cutting edges of the bora do you need to exit outside.

- It is necessary to need a piece of steel corner, on one side of which cuts of up to 4 cm and width equal to the thickness of the cylinder wall are made.

- It is manufactured with a strip metal of 200 * 35 * 3 mm.

- The strip is clamped into the vice and bends into the spiral. The lower part of the spiral is cut at an angle of 45 degrees and sharpened.

- The manufactured drill is welded to the boor.

- Manufacture of a handle for a boraxy.

A piece of reinforcement with a diameter of at least 1 mm and a length of 50 cm is cut in the pipe on which the homemade boring is fixed, the holes are drilled every half meter with an indent, from the top edge, equal to 15 cm. During operation, the reinforcement must be trained in these Holes to rotate the bora.

When you need a big length of the drill rod, you can enroll in one of these methods.

Apply threaded coupling compounds:

- to do this, an outer thread is performed on each cut;

- then the threaded clutches are made in the required quantity;

- to progress from the spontaneous disconnection of parts, a pinned lock is made.

Use welded bolts and nuts welded to the ends of sections. This method is applicable for dumping pipes of small diameters. But this method is not the most reliable thanks to the fragility of the welding compound.

Apply, made in advance, rod sections with bolted fixation. This is a simple and effective way:

- cutting a clutch of a pipe of a larger diameter is performed than the rolling tube;

- then they are welded by the end of one pipe, and the other pipe is free inserted into the coupling:

- each such connection is fixed across the inserted bolt with the nut.

Whole and long drilling pipe will significantly complicate the work.

The best solution is a discerning structure with an optimal section of section equal to 0.8 to 1.2 m.

Thanks to this device it will be easier to select the desired length of the drill pipe and increase it as needed.

Several useful tips that facilitate well drilling by applying handmade homemade borrow:

- you can apply homemade ulute to optimize the process of the ground notch to the surface, as the breed is better to collect in the container;

- if it is difficult to raise the ground to the surface, then you need to build a lever from girlish barrels or login;

- homemade boring is useful for other work in the household.

This tool can dig holes for intake poles or pile foundation.

Video: Bow for well

During the construction of a private residential building or a well-maintained comfortable cottage, it is necessary to consider the water supply and drainage system. The main component of the system is a source of pure water. If the water supply is not supplied to the building, it will have to drill well on the territory of the property. This procedure can be performed independently in the presence of a bora.

The tool is drilled in the soil neat, smooth holes of the required size. It is impossible to perform this work of the usual shovel. To the selection of the tool you need to take very seriously. Here it is worth considering the characteristics of the soil, the estimated depth of the bombing of the aquifer and other moments.

Features

The bee is designed for digging vertical holes of a large depth of small diameter. At the same time, the effort of a person is minimized. The beginning of the well on the surface layer of the soil is called the mouth, the walls of the well across the entire length form the trunk, the end of the well is called a caution.

The main components of any drill are:

- lower bearing pipe;

- tip;

- cutter or cutting part;

- handle;

- drill nozzles;

- auger (screw part of the bora).

The screw portion of the boraar destroys the soil layer, in which drilling occurs, and displays the ground up. The tip shape is acute, but slightly rounded to rapid penetration and enhance the sustainable position of the instrument. If necessary, the handle is easily removed, and the lengthening pipe is attached to the borough, which allows the well to the well to a large depth. The use of boots is extensive: from the manufacture of wells and strengthening pillars for the hedges before landing shrubs and trees.

Views

The most commonly used manual borehole boraners. Several of their species can be distinguished.

Screw

It performs drilling by the method of cutting the soil layer with specialized plates, which are based on the design. Plates are welded at an angle of 90 degrees. So the soil is partially extracted from the wellbore, so the clearance is carried out by shovel manually. At the drills with knives-plates, welded at an angle from 30 to 70 degrees, all the soil easily comes out. Such tools are suitable for the drainage system.

Crown

The design of such a product includes a pipe and a crown that is in the bottom. The crown is performed from a particularly durable material in the form of pointed incisors. This makes it possible for maneuvering.

Drilling with a crown brown is possible only if there are other additional tools: bits, rods, fasteners. When drilling in this case, the chisel is first used, and then the boring.

So that the walls of the well are not destroyed, use water. If the length of the bora is not enough, it is instructed by adding a rod. High-quality care only improves the technical characteristics of the tool.

Shock-rope

This is an unusual large-size tool consisting of a pipe with a vent. To use this type of the bora, you need a tripod. It is installed at an altitude of about 2 meters.

With this form of drilling there is a task to make a well.From the height in it, a high weight pipe is discounted with a sharp end, tied with a thick rope or rope for a tripod. The soil layer is joined and enters the pipe. Then it is removed to the surface with a winch and cleaned from the ground. In such a job, only one person can be occupied.

Spoonful

It includes a long metal rod with a cylinder at the end. The cylinder has 2 components that are located along or in the form of a spiral. At the bottom of the cylinder is a sharp cut edge. While drilling the well, the cylinder is filled with soil, then removed it to clean. Such a type of a boraine is adapted for territories with dense wet soil, not prone to sickness. This tool is often used for the manufacture of wells under water.

Bur spiral or snake

It is used for drilling on dense clay and driving soils, which contain pebbles or small gravel. The components of the elements of such a bera: head with cutting, spiral coils with blades and rod. They work such a brown slowly, calmly turning it deep into it. The soil sticks on the turns, with their full filling of the boring and can be cleaned.

Chisel

This option is great for dry clay or loose sandy and sampling soils. To create it, a piece of steel is used. Drilling is carried out by the method of impact with the subsequent rotation of the tool for 15-20 degrees. Also, bits are used for crushing small stone.

Rod

Rotational or shock drilling can be performed by a rod rod. It requires pipes from 1 to 3 meters long.

Diamond

In particularly durable bases (concrete, stone), drilling are carried out using diamond drills. They are two species: electrical and hydraulic. The electric tool is drilled by small wells. They require electrical current. Certain samples of electrical diamond drills are operated on gasoline or diesel fuel. The use of hydraulic requires the use of a special pump to do large holes.

In the description of the technical capabilities of each type of drills, you can find the following data:maximum drilling depth, well diameter, tool weight. The ease of the work carried out directly depends on its mass. What it is more and harder, the harder it is to work with him.

How to make a car with your own hands

Any craftsman can independently construct a unique car for drilling from its materials and remedies. However, the assembly needs at least the basic skills of metal processing and locksmith skills.

Production of the simplest bora

The easiest in the manufacture of a boring, not having a screw helix, is performed from the handle and the canvas for drilling. The role of the handle can play a pipe made of metal with a diameter of no more than 3 cm. If there is no metal pipe, it can replace the wooden element. For the bead canvases, the steel strip is necessary.

A loop-tip is attached to the working part of the band. On the other side, a slot for the handle is formed. When drilling a tip-loop is clogged with a small amount of soil, which is pulled out on the surface. Then actions are repeated. To obtain the well of the desired depth, several bands are joined and rotated the design.

There is another manufacturer. Take the strip of the length of about one and a half meters long, from 5 to 10 cm wide, a thickness of about 1 cm. Make an indentation of the edge of the strip 8 cm, rush the slot 150x2 mm. The other end of the strip bend into the circle to insert the lever knob.

The working edge of the metal must be accelerated from the gap in different directions, forming an oval. Ribbon near the tip must be cut to get the edge. It must be sharpened and beaten in the opposite direction. Next into the ring you should insert the knob of the lever. She will give the device the ability to make rotational movements.

Production of auger borax

For the manufacture of the apparatus of this species, a pipe with thick walls, a steel disk with a diameter of a future well and a thickness of at least 6 mm. If there is no steel disk, it can be replaced by a disk from the circular saw of the same size.

A sharp steel tip is welded to the pipe, with its absence, they simply sharpen the edge of the pipe until the sharpness is obtained. Then the disc is cut at half. The edges of these halves are pushed to the preparations of the teeth.

Both parts of the disk are welded to the pipe by retreating from the pointed edge of the pipe from different sides by 13 cm at an angle of 65 degrees. The angle between the resulting screw parts should be equal to 40 degrees.

If errors were made when assembling the drill design and a very large angle was put up between the blades, the land from the bora will turn down, and additional efforts will be required to retrieve it. In the upper part of the pipe, the clutch is organized to build the length of the rod (if necessary).

Assembling a spoonful bora

If it is planned to drill well on moving soils with soft soil, it is best to use homemade spoonful borrow. In this case, the loosening of the soil layer will be carried out by the bottom and side surfaces of the structure.

First of all, it is necessary to prepare drawings and everything you need.For the manufacture of a boraner of this type, you need a thick-walled pipe with the walls of more than 5 mm, a welding machine, plumbing tools.

By the longitudinal side of the pipe, a wide section is separated. The width of this cut directly depends on the type of soil. The smaller the stiffness of the soil, the one should be wider, and vice versa. The pipe align and expand, giving it a shape of a spoon. Work is conducted with hammer and scrap. The edges are calcined, the drill is attached at the bottom of the design. In the upper part of the pipe, a bar is installed with a shift of 1 cm to the pipe axis.

Manufacture of shock-cable bora

With a shock method of drilling well, two tools are used: acute pipe and ulute. For the venture, we need a solid alloy, resistant to damage and deformation. It is best for steel and cast iron. Such borants are suitable for the development of aquifer lived a depth of up to 10 meters.

For the design, a pipe is needed with a length of about 85 cm and a diameter of 6 cm, a ball of steel with a diameter of 4 cm, a washer, a metal grill of rods. The washer is tightly fixed at the end of the pipe. The saddle size must correspond to the diameter of the ball. A grill is welding on top of the pipe. It prevents the fallout of the ball. It is also attached an arc of metal to install the venture on a cable or a durable cord. In order for the design to be stronger and efficient, the teeth can be attached to the lower part of the ulute.

To drill a well on the territory of the country area, you will have to use or a mechanical installation, or a manual brown that can be made with your own hands. Of course, if it is planned to organize a well under the well of a great depth, then without installing can not do. But if you want to dig only a small well to 10 m long, then you can use a manual drilling tool for drilling. Let's look at the drawings of the device, as well as the technology of its manufacture.

Structural components of a manual bera

So, the composition of the manual drill includes:

- Rod, made of pipe;

- Knives or auger;

- A pen;

- Tip.

Bar

Let's start with this element as the main in terms of loading. Usually homemade manual drill, or rather its rod, is made of pipe with a diameter of 20-32 mm. If you need to dig up with a well depth to 1.5 m, then the pipe is used for the drum. In the event that you need to drill a well for greater depth, the rod can be increased with additional extension elements. In essence, these are all the same pipes that in different ways can be connected to the Bura rod.

Three ways of compound.

- For this, a thread is cut on the riding side of the handle. The same is done with the ends of the extension element. Then a pre-prepared coupling on half of its length is screwed into the threads of the rod. The coupling is welding to the pipe outside all over the perimeter of the connection. If necessary, lengthen the barrel of the bora, you just need to screw the thread of the extension element in the welded clutch. On the other hand, the pipe will be welded exactly the same coupling, with which all devices can be extended again. By the way, the length of the sections of the detachable bera is 1.0-1.2 m.

- You can use for connecting the bolt and nut sections. That is, the nut is welded to the free end of the trunk, and the bolt to the end of the extension section. Just the bolt will be screwed into the nut. Let's just say this option can be used if the depth of drilling will not exceed 5-6 m.

- The most simple and reliable option is a connection of sections with a pins. It is necessary to take a tube cut (length 8-10 cm) of a larger diameter than the barrel of the bora. Take this coupling to the tool bar, but to pre-make through the through hole, for example, under the M8 bolt. Exactly the same hole must be in the additional section. At the same time, the distance from the end of the coupling to the opening should coincide with the distance from the hole to the edge of the section. The connection itself is performed simply - insert the extension element in the coupling and secure the pin connection (you can use a bolt or smooth fittings as it). Look at the photo below, where the drawings of such a connection are shown.

Attention! Depending on the type of drilling tool chosen by you, the handle will connect with the bar for exactly the same technology.

Pay attention to the length of the handle, this dimensional indicator will depend on how many people will turn the boring. If two, then it is better to make 1 m long, if one, then half meter will be enough.

Knives Bura

This is the main working body. You can make it from different materials or tools. Specialists offer three constructive options that differ strongly from each other.

The first option is a sheet knife, commonly used for drilling small well-diameter. It can be made of leaf iron with a thickness of 2-3 mm. This is done like this.

- Cut with a grinding circle of the required diameter.

- It is cut into two equal halves.

- Under the trunk of the boraine, it is also necessary to cut the semicircles of the required diameter.

- With the help of a grinder and a grinding circle, the edge of the knives is hurned.

- Both knives are welded to the bar at an angle of 20-30 °. The installation site may be one, and you can arrange the cutting elements over the other at a distance of 5 cm.

The second option is to use the cutting disk (you can use used). It can be a disc from a circular or from a clinkering machine. Please note that the internal planting diameter of the tool should be slightly larger than the diameter of the rod. The disc is also cut by the grinder in half, and the segments are welded to the trunk at an angle.

The third design option is the so-called spoonful bur. It is usually used for the construction of deep wells, more than 20 mm. For this, its barrel is made from the pipe with this diameter so that the casing, and the working with all equipment can be placed in the well. At the same time, the manual boron itself is supplied with a strong tip. More often for these purposes use large sizes of drill. But since for wells on country areas, a depth of 10-12 m is sufficient, then the spoonful tool for drilling is rarely used.

Making tip

We will not forget that the tip greatly facilitates the process of drilling wells. It is he who center the direction of the occurrence of a bora in the ground, and also partially breaks the earth. What can be done from?

To do this, you can use a metal strip with a thickness of 4-5 mm and width of 30-40 mm. From one end, the band cuts into the corners, making a peak from it. The edges of the peaks are then sharpened with the help of a grinder and a grinding stone disk planned on it. After that, the other end suits on both sides to make the landing shank, its width should be slightly less than the inner diameter of the trunk pipe. The length of the shank is 5-10 cm.

Now it is necessary to form a tip twist. To do this, it is installed in vice with a peak up. A gas adjustable key is taken in the hands, it is clamped with his lips of the plate and turns counterclockwise. Everything is simple and easy. After that, you need to insert the tip insertion into the rod pipe and cut your electric welding.

The second method of manufacturing the tip for the bora. For this, nothing needs to be added to the design of the tool. Simply at the stage of manufacturing the rod, it is necessary to cut it with a free end to the corner segments, separating the part of them so that a peculiar flower turned out. Only when creating a flower, you need angular petals to turn outward, and in the manufacture of the tip, on the contrary, collect them into a single point so that the peak is, as shown in the photo.

If it is supposed to produce drilling work in a unlightened well, which will be equipped with soft soil, then the boring can be made independently. The manufacturer of the well for the well with their own hands will be able to possess the maximum depth of the well barrel limited to 20 m.

The bore for the well made with their own hands has the maximum depth of a wellbar, limited to 20 m.

Making a bead from disks

The rig of one of the composite elements of the design will be a drilling pipe, its peculiarity is that the length will increase as well shut down. Among the main components also the handle that will be responsible for the possibility of rotating the pipe. This can be carried out by one specialist or two that will speed up the process. Despite the importance of the remaining components, the leading element will be the borough.

Metal born is made of two semi-triys.

You can make a boring with one of the selected technologies. With independent manufacture, it is important to consider that it is necessary to work with the metal, which is why the master must have welding skills and welding equipment.

Before making a boring, it is worth assessing your abilities. If you do not want to give the process overly much time and strength, you can make the simplest tool version that will be represented by a steel rod with a carefully pointed tip.

In the process of manufacture, two knives have to prepare, they must be strengthened by welding method at a distance of 200 mm from the tip.

In order to make a bore for wells, you need to use metal discs with a thickness of 150 mm, which will form the basis of the knives. The disk is to be cut in half.

After installing the knives should be on a tool at a low angle, the maximum value of which is 20 ° with respect to the horizontal. In relation to each other, self-made knives should be opposite.

Thus, an angle of 40 ° should be formed between the welded knives. The lower edges of the knives, which will enjoy the bob, should be carefully sharpened. This is necessary to make much importance, since the speed and simplicity of the insert in the soil will depend on the sharpness of the working surfaces of the tool.

No wonder the factory models of the drills of this type are made from the steel strip, which is heated, and after being twisted, this circumstance with his own manufacturer should be adjusted. The distance between the adjacent twists of one helix should be equal to their diameter. Once the metal turns out to be twisted, it is ordered.

After the manufacturer should be checked for fitness. To do this, they need to produce rotational movements using handle, and ended knives in the process will be delighted into the thickness of the soil. After a certain time, the boring should be removed from the well to dry out a cut ground on the surface.

Tools for the manufacture of a rig: welding machine, Bulgarian, drill, hammer.

The Earth should be folded away from the venue of the drill work. Next, you can continue to work the brown. Before the start of the drilling of the well, you need to worry about where the soil is supposed to be taken, for which you can use the cart.

As the well depth increases, the rod is extensive. In this case, the composite parts should be strengthened with each other by means of a threaded connection, which can be replaced by a sleeve. In order to eliminate the probability of separating the components of the rod, their compounds can also be strengthened with hoptes. After lifting the elongated rod up from its unnecessary links, you can get rid of it. Spiral storms can be used in areas where clay soils and small gravel are present.

Tools and materials

- steel rod;

- steel disk;

- welding machine.

Alternative version of Bura

Using steel sheet, it is necessary to make billets in the form of circles that will become cutting parts. If you make these components by giving them a different diameter, then the tool can be used when drilling different wells. The diameter of the billets should be greater than 5 mm compared to the width of the intended well.

Types of beads: 1 - spoonful boring, 2 - Zmeevik Bur, 3 - Zmeevik, 4 - drill bit.

In the center of the workpiece you need to equip holes, the diameter of which must be 1 mm larger than the diameter of the steel rod, which will become a rack. Now there comes a turn of a lathe, on which the metal sleeves will be preparing, they also need to make two holes and cut into the thread. Subsequently, it will serve to fix the cutting elements on the rack with bolts. The cutting wheel will help cut on the billets of the cutting elements a small area. After it, it is necessary to stretch while holding down in the ends, so that the element began to resemble the screw. The lower edge of the screw base must be compacted with an angle of 60 °.

On the table of the tool you need to make flat sections that will be deepened by 3 mm. It is possible to make them through the emery circle with the retreat from the end of the rack 8 cm.

The lower end of the rack must be formed in the edge, it is for this to be sharpened at an angle of 30 °. The cutting circle will help to make the grooves on the edge. To ensure easier enhancing the drill in dry soil, with the help of the welding machine you need to strengthen the drill to its end. At the opposite end of the rack, you need to set the handle to dismantle it. Its fastening can be performed by a sleeve.

The last stage of the work implies a tool staining, which will protect it from corrosion processes, extinguishing the lifetime of the Bura. The tool will last longer if after using it to clean from the ground, check for the absence of damage and burrs of the edge of the blades. Damaged damage can be eliminated by anti-corrosion paint.

Before using the bora, the upper part of the soil is to be removed by a shovel, after a slightly bursting surface. This will facilitate the entry of the bora.

Production of a spoonful borax

The use of a spoonful type bera is appropriate under ground conditions, which is inclined to squeeze. If we decided to make such a boring to arrange a well, you should give a cylindrical shape to it, in the lateral base of which to equip a longitudinally located slot. The form of the latter can be spiralized. Such a boor, as a rule, is attached length equal to 700 mm, but not more. Removing the soil and hold it in the cylinder cavity occurs due to compression and subsequent sticking. With higher bulk ground indicators, the slot must be made narrower.

In order to make a cylindrical component of the tool, it is permissible to apply the sheet steel that you want to collapse, giving a certain diameter. If you wish to make a bore for a well, you can pick up a piece of the pipe of the desired size.

The advantage of such a boom to arrange the well is that the soil removal is made both horizontally and vertically arranged edges. You can perform a slightly different variation of the tool to arrange the wells with your own hands, in this case, to the bottom you need to attach the drill to be installed along the axis of the bar. If you select the basic characteristic of a similar drilling drill, it is that the axes of drill and rods must coincide, unlike the line axis line and the cutting longitudinal edge, which are located with a displacement of 1.5 mm in relation to the main axial line.

Such beras for wells, having a similar mutual location of the axes, help that have a larger diameter than the tool itself. It became possible to achieve due to the extraction of the soil from the side walls of the mine through a longitudinally located cutting edge. In order to free such a burden when drilling wells from the soil, it will also be periodically raised. A spoonful meager is able to overcome the inner space of casing, mounted to prevent the shaft collapse.

If you still think about whether to make wells, perhaps the following circumstances will help you to incline your choice in the right direction. An independent manufacture of such tools allows you to save on the purchase of new, as you can use those materials and tools that each wizard have.

Handbreak, when it is necessary to independently equip the well, is able to exclude a disturbance of a site landscape, which is inevitable when drilling through special equipment. However, there are also disadvantages expressed in limiting the depth of the structure. And if there is a dense soil on the site, the manufacture of a manual drill is better and not start, as its operation will be impossible. Having made a homemade boring, you can also use it in the construction of fences, installation of pile foundations and planting plants.

In order to equip in the garden plot, the autonomous water supply system is not at all necessary to build an expensive artesian well, the price of which can be incomparable with the needs of water supply. It will more reasonably be made a shallow well on the sand, the resources of which is quite enough for the water supply of any country area of \u200b\u200bseasonal use.

Provided that the groundwater is located at a small depth, and the composition of the soil on the site does not contain rock rocks and consists mainly of sandy and clay soil layers, such a well can be made independently with the help of simple drilling devices.

Manual drilling wells

This article will talk about how to make the brunt to drilling wells with a depth of 20 meters without the use of special heavy machinery.

The reader will propose instructions for the manufacture of three types of homemade devices for manual drilling of wells, which were most common among garden land owners.

In addition to the description, this article contains the drawings of a bore for a well with their own hands, according to which, in the presence of workshop work experience, you can make a simple drilling tool.

Shock-rope drilling

This type of drilling work is convenient because it does not require the manufacture of any special devices, and the drilling rig can be collected from infirred materials. In addition, it allows you to carry out all the work independently without any help.

The essence of this type of drilling is as follows:

- in the well with a high height, a heavy tube with a pointed end is reset to the rope.

- Under the influence of its weight when falling on the bottom of the well walls of the pipe cut into the body of the face, and some of the soil enters the pipe.

- After that, the pipe is raised to a certain height and sharply discard down.

- Gradually, the well deepens, and the grounding ground accumulates in the shock tube.

- After several blows, the pipe is removed to the surface with a manual or electric winch for cleaning it.

- After lifting the shock head, it is assigned to the side and is cleaned from the drilling rock with several blows of heavy hammer, and then the entire process begins again.

Shock

Thus, drilling continues until the required well depth is reached.

- Above the intended place of drilling a well to establish a tripod high 2-3 m.

- At its vertex you need to fix the block for the rope, and to one or two supports to attach a manual or electric winch.

- The shock bee is a thick-walled pipe that should correspond to the diameter of the extension well.

- To the upper end of the pipe perpendicular to its longitudinal axis, it is necessary to weld a strip of thick metal with a hole, the diameter of which must correspond to the thickness of the lifting rope. Hole should be positioned along the axial line of the pipe.

- On the lower end of the pipe it is necessary to perform a ring or shotch. If possible, after sharpening it is desirable to temper the end in a muffle furnace.

- To facilitate purification from the soil at the top of the pipe, you can make a slot or drill several radial holes.

Tip! If the power of the winch allows to accelerate the work, you can increase the weight of the drum drum, installing additional removable metal loads in its upper part.

Articles on the topic:

Rotary drilling

This type of work is characterized by the fact that the working tool is crashed into the ground and takes out the residual rock under the action of the rotation forces. To perform this work, it is used, as a rule, two people who are located on both sides of the drilling rod and rotate it with a turn of a long scrap or steel pipe.

Thus, a shallow water well in the sand can be made in a short time without using any additional equipment. All that this will require this manual car the necessary diameter, the rod to build the length of the working tool, the two pipes for the turning length of sufficient length and several days of free time.

Spiral bur

For manual drilling of wells in the lungs, not stony soils, one of two types of working tools are most often used: spiral and spoonful boos.

Spiral (it is also called a screw) Bur in the working position is a vertical bar of a thick-walled pipe, in the lower end of which a carbide cutting tool is installed. Along the rod up from the cutting edge, spiral strips of tempered steel are welded.

When rotating, the cutting edge cuts up soil, and the spiral stripes push it up, thereby creating an additional focus in the direction of drilling. In the process of operation, the residual soil from the well accumulates between the screws of the auger, so it must be pulled out to be pulled out to the surface for cleaning.

Before making a bore for a well, you need to prepare a thick-walled pipe of the required length and a metal disc from steel with a thickness of 4-6 mm, an outer diameter equal to the diameter of the well.

- The lower end of the pipe must be sharpened or screwed into it sharpened tip from tempered steel.

- Metal disk Split in half and on the cutting edge of each half to perform a flat or gear sharpening.

- Halves of a steel disk to weld to the vertical bar at a distance of 125 mm from the pointed end from the opposite sides at an angle of 70 ° to its longitudinal axis. Thus, the angle between them should be 40 °.

- At the top of the rod, install a threaded coupling for extension it in length.

Tip! As part of the auger, you can use the saw blade cut from the circular saw of the corresponding diameter.

Spoonful

To work in soft, squeezing clay or sandy soils, you can use a border. It is convenient because the opening of the soil is performed not only by the bottom, but also the side cutting edge, collecting the selected breed inside the cylinder. It also requires periodic removal of the working tool from the well to the surface.

To make such a device, a thick-walled pipe of the suitable diameter, a welding machine and a standard set of plumbing tools will be needed.

- In the tube segment it is necessary to make a longitudinal slot according to the drawing.

- With a heavy hammer and a flat tip scrap, give the pipe the required section.

- Run the bottom and side cutting edges.

- In the lower part of the pipe along its longitudinal axis, to spend thick drill with a diameter of 18-36 mm.

- To the top of the pipe to weld the vertical bar. The longitudinal axis of the bar must be shifted towards relatively longitudinal axis of the working tool by 10-15 mm.

Tip! The width of the slot in the pipe depends on the composition of the soil and is selected by experimentally. The more dry and loose soil is on the plot, the less the width should be a slot

Conclusion

After reading this article, it can be concluded that with favorable geological conditions, you can use homemade equipment to make a shallow well on your own garden plot forces of one or two.

Additional information on this issue can be obtained by looking at the video in this article or reading similar materials of our site.